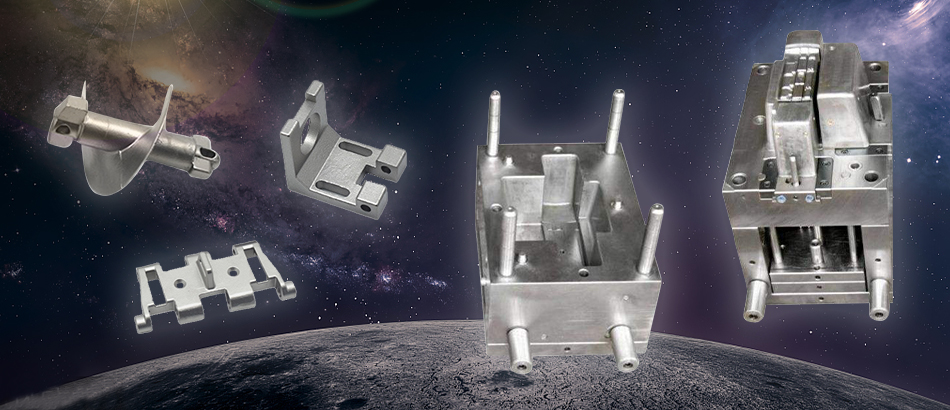

Die-casting molding

Bess manufactures high quality die cast tools, offer precision die casting and post process machining and finishing options.

Similar to injection molding but for metals, a mold tool is first manufactured by Bess’s highly skilled toolmakers and engineers. This is then installed on a die casting press and molten metal is injected under pressure into the tool cavity. The parts can then be finished in a range of ways including powder coating and anodizing.

Advantages of Die Casting

● Lower cost per part

● Accurate and repeatable

● Good surface finish and range of treatments

● Good for larger and more complex parts

Anna Chan

Anna Chan +86 135 4246 7944

+86 135 4246 7944